hardness test result|types of hardness tests : inc The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell . No baixaki você encontra os apps e programas mais buscad.

{plog:ftitle_list}

WEB747 APP 100K | 747 RAFFLE 257K DAILY. Participate in live casino tournaments to experience the true rush. Play, watch, and place bets on your preferred casino games.

The Rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the Rockwell formula. The resulting value is then translated to the .

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . Normal results are usually between 2 and 7 kPa. Your result may be higher than the normal range if you have liver disease. The highest possible result is 75 kPa. Using Your Liver Stiffness Result to Find Your Fibrosis Score. Your healthcare provider will use your liver stiffness result and medical history to find out your fibrosis score.

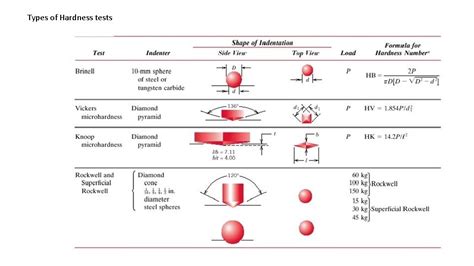

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness testing is used for two general characterizations 1.Material Characteristics • Test to check material • Test hardenability • Test to confirm process • Can be used to predict Tensile strength 2.

types of hardness tests

types of hardness testing methods

This publication is designed to help people interpret drinking water test results. It lists all the major constituents in typical water and their significance. The primary target audience are homeowners with their own water supply but it is also used by people on public water supplies. A list of laboratories that test water is also included.The minimum distances between test points (indentations) and to the specimen edge, which are used for the Vickers test method are defined in standard ISO 6507.The reason for these minimum distances is to avoid distortion of the hardness testing results, which could result from the deformation of the material structure.The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. The Pencil Hardness Test is a widely used method for assessing the hardness and scratch resistance of coatings and materials. This simple yet effective test provides valuable insights into the durability and quality of various surfaces. . Any impurities could affect the test results. Apply Constant Load: Place the pencil in a holder with a .

Paramount to accurate and reliable Rockwell hardness results is ensuring that the operators and the methods used are following proper test technique and practice. The precise nature and exactness of a Rockwell test require following strict hardness protocol and adherence to standards. . For the lowest hardness test force, the 15 Kgf scales, a . These heat-treated samples were then tested mechanically using the Brinell hardness test (BH). The results show that the quenching mediums affect the mechanical properties and hence the .Often, water hardness test results will be delivered in ppm or mg/L, which are equivalent. To use the same hardness scale above, you can simply convert your ppm or mg/L by dividing that number by 17.1 to find the gpg equivalent. So, for example, 130 mg/L or ppm would be 7.6 gpg, which is considered hard water.

In the Rockwell hardness test, an indenter is pressed into the material. . that the material will only bulged out on the opposite side due to the high test force and thus falsify the measurement result. For this reason, variant A was introduced for diamond cone testing, which operates with a reduced test force of 490 N (50 kp). In addition . This process will result in the formation of a spherical indentation, and the load value per unit area of the indentation is considered as the Brinell hardness of the metal material. . Hardness test characteristics. ① The stress state is very soft (α>2), which is widely applicable;

types of hardness testers

A numerical hardness value is assigned to the test material based on the results of the test. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc .The Janka hardness test results tabulated below followed ASTM D 1037-12 testing methods. Lumber stocks tested range from 1" to 2" (25–50 mm) thick. The tabulated Janka hardness numbers are an average. There is a standard deviation associated with each species, but these values are not given.

Before application of the Rockwell hardness test, you must prepare the surface of the material to be tested. The required surface condition for the Rockwell hardness test depends on the load used. The Rockwell hardness test is .Using an incorrect indenter may result in inaccurate hardness values. Scale Variation: Different hardness scales exist for various materials and testing methods. Understanding which scale to use for a specific material can be challenging. . Shore Hardness Test: Specifically designed for elastomers and plastics, this test measures the material . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially valuable for micro hardness testing requiring small, accurate measurements. . Hardness Testing Results for Reliable Material Performance. Hardness testing is a . 📊 What To Know When Interpreting Your Test Results. To be able to interpret your test results, you need to know how water hardness is measured. 👨🔬 Water hardness is measured in GPG (grains per gallon). You can convert GPG to mg/L (milligrams per liter) or parts per million (PPM) easily. For example: 7 GPG of hardness is equal to 120 .

Lab Fiber Classifier Φ300 store

The Shore D Hardness test is also called Durometer Hardness Test. The letter "D" symbolizes the type of durometer used to measure the hardness of a material. It is a dimensionless quantity. . Vulcanization of the material – Keep the material away from harsh conditions before conducting a hardness test. They may give a false negative result . Learn how to test and measure water hardness & how to interpret your test results and effectively solve your hard water problems. Read More . 16 Aug 2021 . Read More Posted By: Beatrice Stone . 0 Comments .As a result hardness values are typically reported in units of pressure, although this is only a "true" pressure if the indenter and surface interface is perfectly flat. . Widely used to test hardness of all kinds of metal materials (steel, nonferrous metals, tinsel, cemented carbide, sheet metal, etc.); surface layer / coating (Carburization .inert solvent, or a soft eraser; taking care not to affect the hardness of the coating in the test area or the result of the test. You then assess the test area through close visual inspection, by touch using a fingernail, or both. And if agreed, it is even possible to inspect using a magnifier of x6 to x10 magnification, such as the Elcometer 137.

As a result, the more anchor points added, the harder the material will become. . Janka hardness test; Nanoindentation; Barcol hardness test References Further reading. Chinn, R. L. (2009). "Hardness, bearings, and the Rockwells". Advanced Materials & Processes. 167 . When the Brinell hardness (HB) exceeds 450 or the sample is too small, the Rockwell hardness test is used instead. This test involves pressing a diamond cone with a 120° top angle or a steel ball (1.59mm or 3.18mm in diameter) into the material’s surface under a specific load. . Therefore, higher material strength generally results in .The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .

hardness tester for thin material

Pode conferir! Games de todos os tipos e para todos os gostos, escolhidos e catalogados para você achar fácil. Encontre os melhores jogos para jogar sozinho, para jogar com .

hardness test result|types of hardness tests